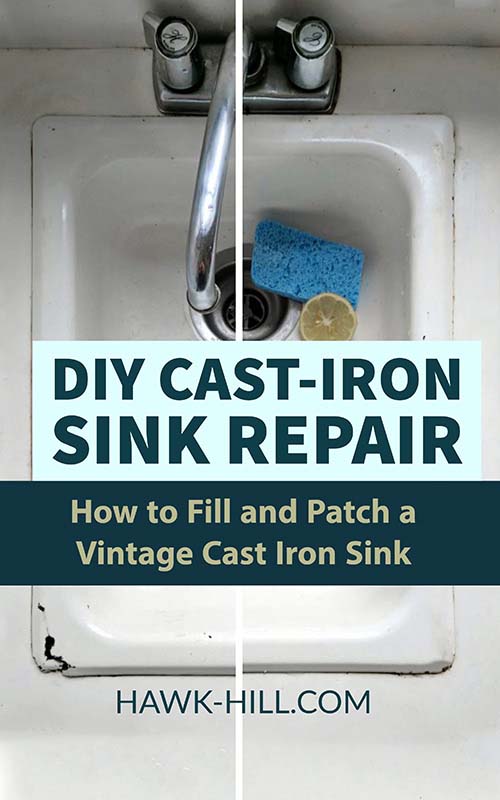

How To Repair A Rusty Sink

Living in Seattle on a grad schoolhouse budget meant having to sometimes settle for a lifestyle very unlike from the one I lived in Missouri merely a few years ago.

With Seattle'due south booming tech industry, housing on a grad schoolhouse budget usually implies lots of roommates or ultra-tiny studios (some students I knew even lived in apartment buildings where kitchens and bathrooms were shared by a whole floor!) I was very lucky to notice an old apartment building in the old downtown neighborhood of Seattle, just ii blocks from Motorway Place Market, where I was able to rent a small- but not "micro" – studio apartment in my price range. Though it had lots of drawbacks, the high ceilings and Puget Sound views, along with a lot of vintage amuse, made it a great find.

The Kitchen Eyesore

When I moved in, my sink had a few rusty spots. Unfortunately, the tiny kitchen was so small that it required boat-galley-kitchen equipment, and the visitor that produced the sinks for my building had long since gone out of business: and so no replacement. Most of the kitchens in my building been "upgraded" to miniature versions of industrial kitchen equipment – stand-alone stainless steel sinks, etc. And while my apartment manager was willing to do the same "ugrade" (ugly + upgrade) on my apartment, I was afraid I'd lose the lovely vintage feel in my unit that made my space experience so much like home.

Products linked below have been researched and tested on this project. As an amazon associate, we earn from qualifying purchases.

So, I decided to try taking a stab at repairing the old cast-iron sink in my apartment kitchen. The farmhouse at Hawk Hill House had a vintage sink in the basement that had been badly damaged. I always wanted to repair it and bring it up to install in the mudroom simply I never took on the project – always scared I'd make the damaged sink look worse than it did already. Commercial estimates to repair the damage to that farmhouse sink ranged upwards of $400, so that lovely former sink remained in the basement until I sold the property in 2022.

This time, as my sink began to dethrone further, I decided it was now or never – I could either effort repairing the rusty spot on my cast atomic number 26 sink, or I could give upwards and let the apartment direction drop an ugly modern sink into my 120-twelvemonth-old apartment.

To repair my sink I just needed a few items

- metallic filler

- epoxy sink paint

- citric acrid

- fine-grain sand paper

- and an easy-to-remove-tape to go along the epoxy paint off the counter (I actually used contact paper to protect my counter)

2 essential supplies that made this a quick DIY:

Footstep 1: Remove Rust from Sink:

The first step was to clean the sink and scrubbed the rusty parts. I used a toothbrush to make clean around and IN the rusty portions, removing whatever and all loose debris.

Food grade citric acid can exist helpful to eat abroad rusted portions without scrubbing, just mix powdered citric acid with a bit of hot water, dissolve, and saturate the rusty surface area. Ideally, you can remove all rust for the "perfect fix," but if you are just looking to go a few more years out of a bandage iron sink with a expiry wish, you can do your best, leave some rust, and expect to demand to repeat this process or replace eventually.

Step 2: Allow to Dry and Protect Surrounding Surfaces

One time your rusty spot has been de-rusted as much every bit possible, allow the expanse to dry thoroughly from any water used during cleaning and lay down a layer to protect your countertop.

In these photos, you tin see that I employ some scraps of marble finish contact paper as an piece of cake mode to protect large surfaces from any stray epoxy or paint. Similar to taping the trim in a room before painting, protecting the surrounding surfaces both made the job easier and guaranteed a better-looking terminate.

Step 3: Insert Metal Filler

Before the outside could be refinished, I needed to fill the gaps in spaces where rest had eaten through the porcelain and cast-iron. Thankfully, I wasn't the first person to need to patch and fill up corroded metal – and this Devcon epoxy metallic filler fabricated the process piece of cake. Working in about three stages – I had to permit each layer to dry before it added another in social club to fill this very deep gap – I was able to completely fill the gaping pigsty in this rusted bandage iron sink.

Once dry, this metallic patch is as hard every bit metal, and in one case the epoxy appliance paint is added information technology volition be every bit as waterproof. It's a swell choice for a DIY vintage cast-iron sink repair.

Step 4: Sand and Cease Hardened Cast Atomic number 26 Filler

One time the metal filler is completely dry (cured?) It'south time to file it down to a smooth finish. One time dry, information technology'll lighten in color and look a piffling something similar this:

Begins sanding the metal filler downwards to a smooth finish using progressively finer sandpaper. I'm gonna make a DIY confession here: I rushed this portion of the job and I regret it. I didn't accept the range of sandpaper needed to sand down the bumps and add an ultra-smooth stop. Simply I was impatient, and so I continued to the next step.

Stride five: Make clean Sanded Filler

It's very important to remove all of the fine particles created in the sanding process. You tin wash the area and allowed to dry out – or clean with a cloth soaked in rubbing alcohol. The booze evaporates quickly, allowing you to go along on to the next step within a few minutes.

Step 6: Paint with Appliance Epoxy

Appliance epoxy is not regular pigment – it'due south super heavy duty paint with an ultra hard finish that can stand up to just about anything except ultra loftier heat (special appliance pigment is sold for repairing enamel chips on stoves). It's a perfect choice for minor repairs on vintage cast-iron or porcelain bathtubs and sinks. In this instance, it's a comprehend-upwardly that will better the await and add a few more than years of usability to my doomed sink.

Using a small paintbrush, I mixed the paint together and added a waterproof white coating over this gray metal filler.

After the paint dried, I was able to peel away the contact paper revealing and unscathed countertop.

Project Complete

While not exactly a rags-to-riches story, this functional DIY did add a few more years of life to my adorably unique vintage kitchen and its irreplaceable custom sink.

Source: https://www.hawk-hill.com/patch-a-rusty-sink/

Posted by: hardenbace1941.blogspot.com

0 Response to "How To Repair A Rusty Sink"

Post a Comment